Home >Torque Coil for Medical Endoscope and Catheter

Torque Coil for Medical Endoscope and Catheter

About torque coil (torque tube/torque spring)

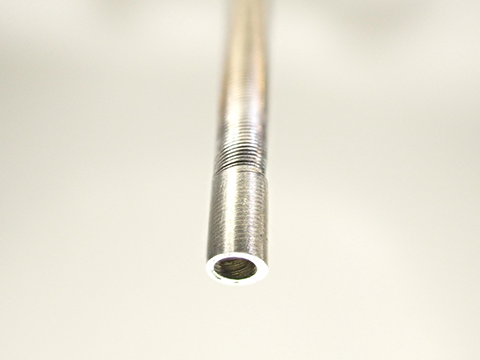

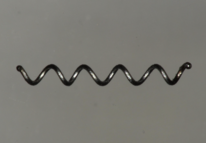

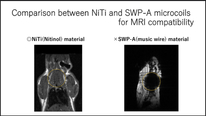

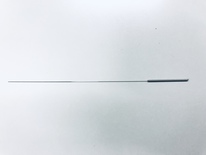

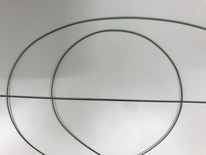

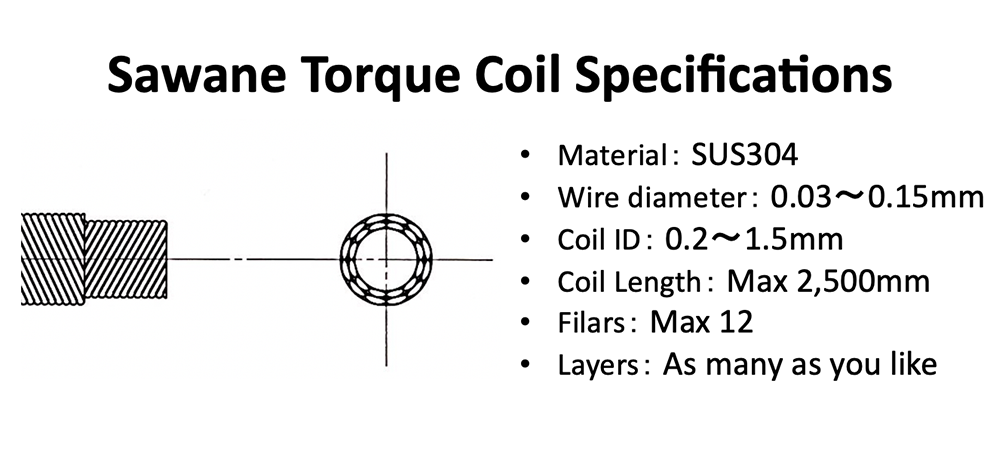

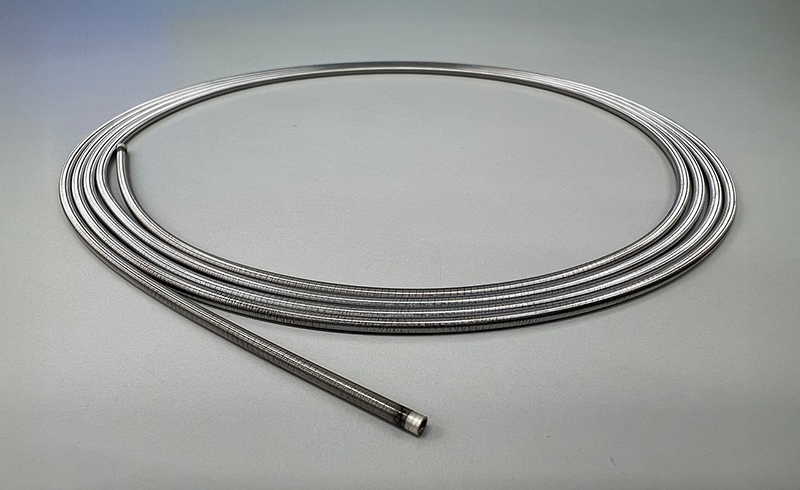

Our torque coil (torque tube/torque spring) used for medical endoscope and catheter has torque transmission with following characteristics. Available wire diameter of SUS304/316 is 0.03-0.25mm, both round and flat wires. Inside diameter of the coil can be 0.1-1.5mm. Maximum coil length can be 2,600mm. Filar count is up to 12 and layer count is usually 1-3 but more layers are available. Medical device manufacturers and researchers all over the world use our torque coils on their new prototyping phases. Prototypes can be made in as little as 1 week. Feel free to let us know if you would like to make new endoscopes or catheters. Our strength lies in quickly producing small-lot prototypes.

Manufacturing technology

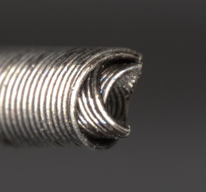

We are capable of winding 1 to 12 wires simultaneously, using both round and flat wire, and can also produce multi-layer configurations as required. Moreover, we can wind wires with coil pitch to adjust flexibility of the coil by our in-house designed machines. Coil ends are either brazed or laser-welded and ground.

| ID (mm) | OD(mm) | Length (mm) | Filar count | Layer count |

|---|---|---|---|---|

| 0.26 | 0.50 | 1,700 | 10 | 2 |

| 0.42 | 0.70 | 2,000 | 12 | 2 |

| 0.9 | 1.80 | 2,500 | 12 | 3 |

| ID (mm) | OD(mm) | Length (mm) | Filar count | Layer count |

|---|---|---|---|---|

| 0.75 | 0.99 | 1,600 | 6 | 2 |

Torque transmission movie

Prototype Example

We made prototype of 2pcs within 2 weeks as follows.

Prototype Flow

- Let us know your torque coil specifications:

1)material, 2)wire diameter, 3)outside diameter or inside diameter of the coil,

4)length, 5)filar count, 6)layer count, 7)direction of helix - Minimum order quantity: 1~10pcs

- Prototype fee : $600~1,200US including shipping cost by FedEx but you will be charged for customs duty

- Lead time: 2~4 weeks

- Payment: Advance payment by bank wire transfer or credit card

*Which way would you prefer? - Let me know your company name, ship to address, contact person and phone number for shipping.

- We make an invoice for your advance payment.

- Once we confirm your payment, we arrange shipping by FedEx.

Manufacturing technology

We can wind multi-wire from 1 up to 12 wires at a time, and also multi-layer as many layers as you need. Moreover, we can wind wires with coil pitch to adjust flexibility of the coil by our in-house designed machinery. Coil ends are brazed and ground. Laser processing would be available in the near future.